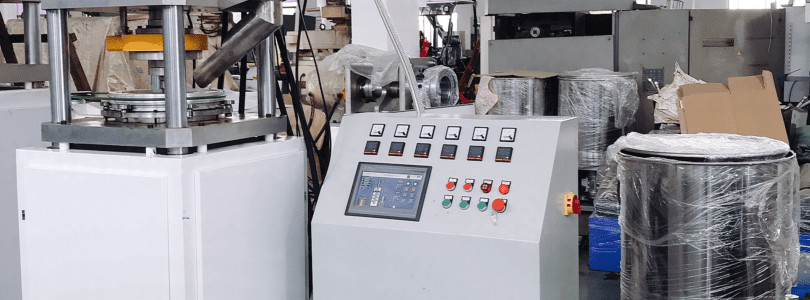

PTFE Hose Extruders: Key Features and Benefits

Introduction Polytetrafluoroethylene (PTFE) hose extruders are indispensable in the modern manufacturing of flexible, chemical-resistant hose solutions for various industries such as pharmaceuticals, automotive, food processing, …