How ordinary items are made using plastic injection molding

Increasing use of thermoplastics in manufacturing took place during the middle of the past century, coming on especially strong during the war years, 1940-45, where …

How to Avoid Injection Molding Defects

When working with any manufacturing process, a number of defects unique to that process commonly occur. This is true across many processes and industries, including …

Plastic Injection Molding Terms

Parting line – A line on a part formed when the two sides of the mold come together. Polymer – A substance that has a …

Questions to Consider Before Getting an Injection Molding Quote

Injection molding is the most common plastic molding process and is used to create a wide variety of complex parts of different size and shape. …

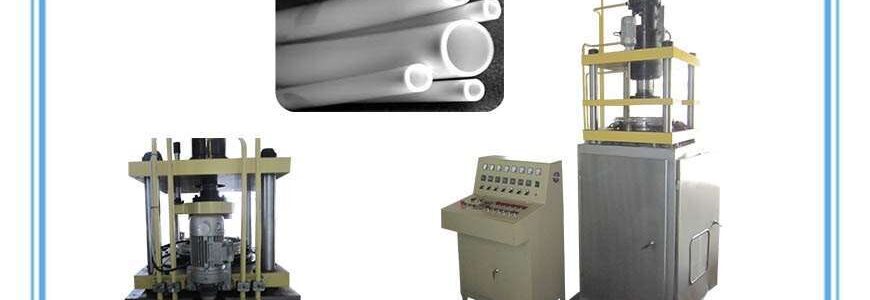

Where to Source Plastic Molding Machine

Automatic molding, a semi-automated form of compression molding, is the process Sunkoo uses for the manufacture of medium-volume to large-volume net molded and near net …

Plastic Machinery Manufacturer

Sunkoo’s enormous strength comes from a wonderful combination of its highly efficient and professional management and a dedicated workforce of qualified and experienced engineers and …

What Is a Plastic Extrusion Operator?

Extrusion operators, sometimes called extruding and drawing machine operators, control and monitor machines that shape thermoplastic materials. They work in a number of manufacturing industries, …

Extrusion Methods

By plasticizing, there are dry extrusion and wet extrusion processes and by pressurizing there are continuous and intermittent extrusion processes Continuous production yields a high …