New vs. Refurbished PTFE Equipment: Total Cost of Ownership Analysis

Introduction: The Real Cost of PTFE Processing

With the global PTFE equipment market projected to reach $2.8B by 2029 (Grand View Research), manufacturers face critical decisions between new and refurbished solutions. This analysis breaks down financial and operational factors across equipment lifecycles.

Key Cost Components Comparison

1. Initial Investment Analysis

| Cost Factor | New PTFE Machine | Refurbished Equipment |

|---|---|---|

| Base Price | $450,000-$800,000 | $180,000-$350,000 |

| Installation | 15-20% of machine cost | 25-35% of machine cost |

| Warranty | 3-5 years full coverage | 6-12 months limited |

2. Operational Efficiency Metrics

Performance data from 50+ PTFE extrusion plants:

| Parameter | New Equipment | Refurbished |

|---|---|---|

| Output Consistency | ±0.8% | ±2.5% |

| Energy Use/kg | 18-22 kWh | 28-35 kWh |

| Uptime | 96.5% | 89.2% |

3. Maintenance Cost Projections

| Year | New PTFE Extruder | Refurbished |

|---|---|---|

| 1-3 | $8,000/yr | $18,000/yr |

| 4-7 | $12,000/yr | $24,000/yr |

| 8+ | $20,000/yr | N/A (replacement) |

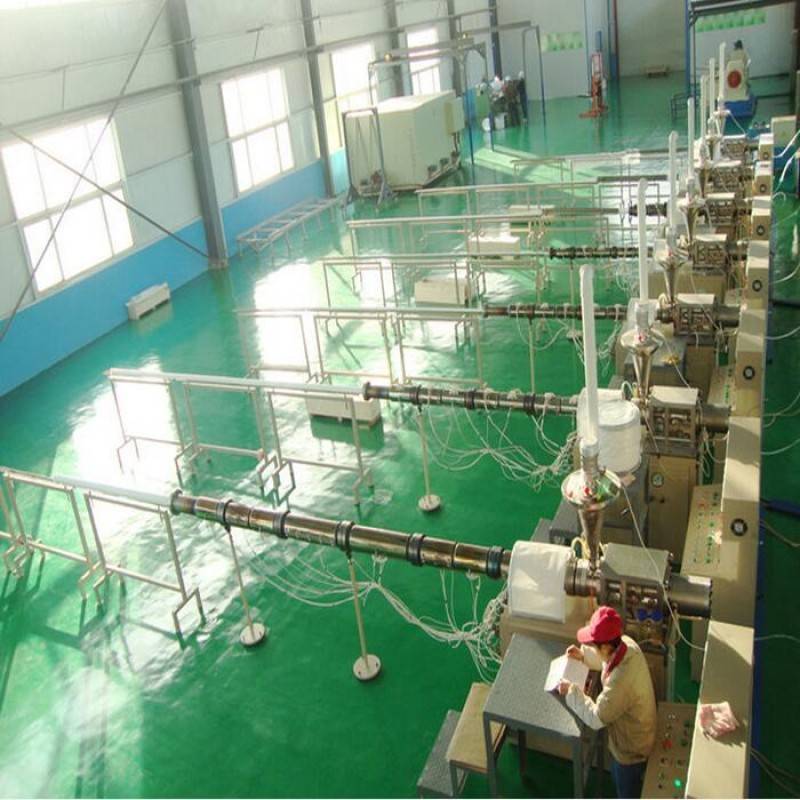

Technical Specifications Breakdown

Critical Components Comparison

| Component | New PTFE Machine | Refurbished Standard |

|---|---|---|

| Screw Life | 25,000-30,000 hrs | 12,000-18,000 hrs |

| Heater Accuracy | ±0.5°C | ±2°C |

| Control System | IoT-enabled | PLC-based |

Industry Certification Requirements

- New Equipment: CE Marking, ISO 13849-1 (Safety), UL 508A (Controls)

- Refurbished: NFPA 79 re-certification, ASME BPE revalidation

Market Data Insights

According to Intertek (2023 survey):

- 62% of refurbished PTFE machines require upgrades within 3 years

- New extrusion systems show 38% lower scrap rates

- Resale value retention: 45-50% for new vs. 15-20% for refurbished

Decision-Making Framework

Total Cost Formula

TCO = Initial Cost + (Annual OpEx × Years) – Residual Value

Example Calculation:

New PTFE extruder machine: $600,000 + ($150,000 × 10) – $270,000 = $1.83M

Refurbished: $250,000 + ($210,000 × 7) – $40,000 = $1.74M

FAQ Section

What certifications validate refurbished PTFE equipment quality?

Seek SPR (Society of Professional Rebuilders) certification and third-party inspections meeting ASTM E2500 standards.

How do lead times compare between equipment types?

New PTFE extrusion machines typically require 14-18 weeks for delivery versus 6-8 weeks for certified refurbished units.

Conclusion: Actionable Recommendations

- Calculate 10-year TCO using verified maintenance histories

- Require component-level refurbishment reports

- Verify OEM software compatibility for upgraded systems

- Compare energy efficiency using DOE’s MEASUR tools