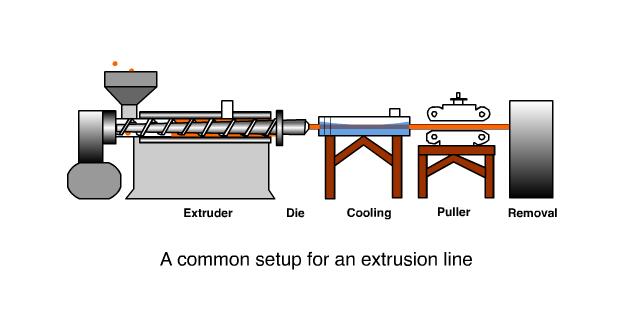

In the extrusion of plastics, the raw compound material is commonly in the form of nurdles (small beads, often called resin) that are gravity fed from a top mounted hopper into the barrel of the extruder. Additives such as colorants and UV inhibitors (in either liquid or pellet form) are often used and can be mixed into the resin prior to arriving at the hopper. The process has much in common with plastic injection molding from the point of the extruder technology though it differs in that it is usually a continuous process. While pultrusion can offer many similar profiles in continuous lengths, usually with added reinforcing, this is achieved by pulling the finished product out of a die instead of extruding the polymer melt through a die.

The material enters through the feed throat (an opening near the rear of the barrel) and comes into contact with the screw. The rotating screw (normally turning at e.g 120 rpm) forces the plastic beads forward into the heated barrel. The desired extrusion temperature is rarely equal to the set temperature of the barrel due to viscous heating and other effects. In most processes, a heating profile is set for the barrel in which three or more independent PID-controlled heater zones gradually increase the temperature of the barrel from the rear (where the plastic enters) to the front. This allows the plastic beads to melt gradually as they are pushed through the barrel and lowers the risk of overheating which may cause degradation in the polymer.

Extra heat is contributed by the intense pressure and friction taking place inside the barrel. In fact, if an extrusion line is running certain materials fast enough, the heaters can be shut off and the melt temperature maintained by pressure and friction alone inside the barrel. In most extruders, cooling fans are present to keep the temperature below a set value if too much heat is generated. If forced air cooling proves insufficient then cast-in cooling jackets are employed.

At the front of the barrel, the molten plastic leaves the screw and travels through a screen pack to remove any contaminants in the melt. The screens are reinforced by a breaker plate (a thick metal puck with many holes drilled through it) since the pressure at this point can exceed 5,000 psi (34 MPa). The screen pack/breaker plate assembly also serves to create back pressure in the barrel. Back pressure is required for uniform melting and proper mixing of the polymer, and how much pressure is generated can be “tweaked” by varying screen pack composition (the number of screens, their wire weave size, and other parameters). This breaker plate and screen pack combination also eliminates the “rotational memory” of the molten plastic an creates instead, “longitudinal memory”.

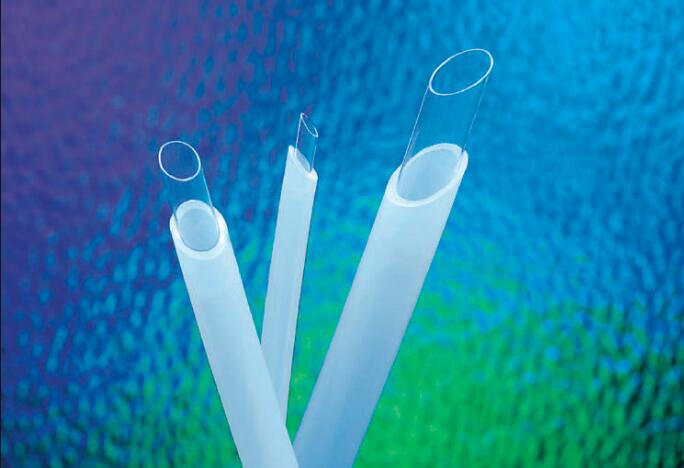

After passing through the breaker plate molten plastic enters the die. The die is what gives the final product its profile and must be designed so that the molten plastic evenly flows from a cylindrical profile, to the product’s profile shape. Uneven flow at this stage can produce a product with unwanted residual stresses at certain points in the profile which can cause warping upon cooling. A wide variety of shapes can be created, restricted to continuous profiles.

The product must now be cooled and this is usually achieved by pulling the extrudate through a water bath. Plastics are very good thermal insulators and are therefore difficult to cool quickly. Compared to steel, plastic conducts its heat away 2,000 times more slowly. In a tube or pipe extrusion line, a sealed water bath is acted upon by a carefully controlled vacuum to keep the newly formed and still molten tube or pipe from collapsing. For products such as plastic sheeting, the cooling is achieved by pulling through a set of cooling rolls. For films and very thin sheeting, air cooling can be effective as an initial cooling stage, as in blown film extrusion.

Plastic extruders are also extensively used to reprocess recycled plastic waste or other raw materials after cleaning, sorting and/or blending. This material is commonly extruded into filaments suitable for chopping into the bead or pellet stock to use as a precursor for further processing.