The quality of medical devices bears upon the health and safety of patients, so the quality testing of medical devices is extremely strict. Medical products will be subject to various quality tests before leaving the factory, most of which have to receive seal testing, e.g., multi lumen tubing used in a multitude of minimally invasive clinical procedures. In order to help you better understand how manufacturers conduct seal testing of medical multi-lumen tubes, SuKo will share with you a case of medical multi-lumen tube seal testing.

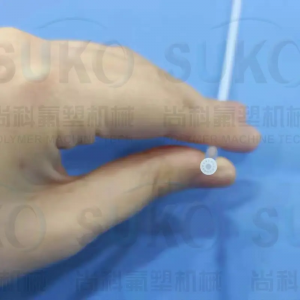

Multi-lumen tubing has a single tube with multiple internal pathways/lumens isolated from one another. The central venous catheter in a multi-lumen tubing has a cut-out tip with small holes exiting from each lumen. A tooling fixture needs to be made to snap and seal the tubing before the seal testing.

To conduct seal testing of multi-lumen tubing, an air tightness tester with 4 test ports should be used with a tooling fixture using pressure-decay method. Before testing, the test pressure, inflation time, pressure stabilization time, test time and upper limit of leakage rate should be set on the air tightness tester, and the multi-lumen tubing should be placed in the fixture, with the proximal end of the lumen connected to the appropriate port and the distal end sealed.

When the tester is started, each lumen is tested individually for leaks, while all other untested lumens are vented. In this way, the leak test detects any cross-lumen leaks as well as leaks outside the multi lumen medical tubing. Once the leak test is completed, the tester will display the final test results with a green light for PASS and a red light for FAIL.

If you have any medical multi-lumen tubing to receive seal testing, please find third-party inspection organization with CMA and CNAS certification.