single screw:In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape.

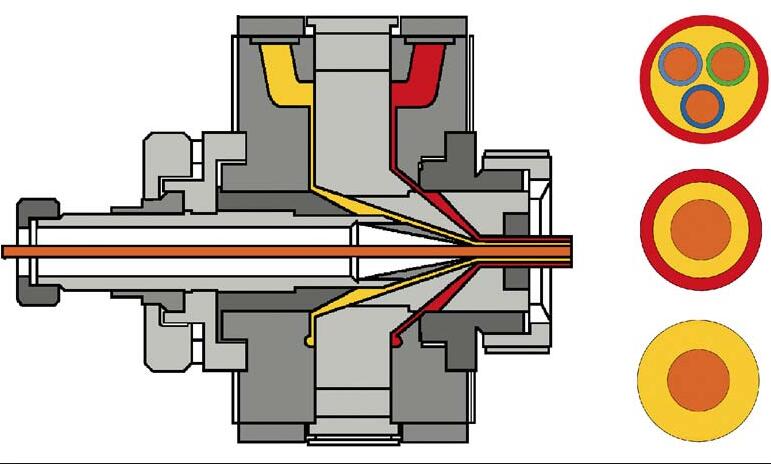

Twin screw:Twin screw extruders have two intermeshing screws and operate in the same manner as a single screw extruder. The picture below shows the barrels of the extruder exposed. Twin screw extruders depend minimally on the friction of the material against the barrel to move forward. They rely instead on the properties of the extruder and the screws. The two most important features are the meshing characteristics and the type of rotation.

Compared to single screw extruder, double screw extruder has below features:

- 1) Material flow is stable, uneasy happen cutoff or billow, productive process is reliable.

- 2) Most heat of double screw extruder mainly come from mechanical transformation during operation, small amount of heat comes from the heating jacket. The single screw extruder often require additional equipment preheat quenched materials.

- 3) Time distribution is relatively narrow range of material retained in the machine, which is easier to control the temperature of the material, sufficient energy utilization, yield and quality are very stable.

- 4) Double screw extruder has a screw surface self-cleaning effect, so that the transportation of materials is stable, little residual material in cavity when finish working, and no need stop to cleaning if change the production material.

- 5) Double screw extruder has large productivity, is appropriate for processing of materials containing high oil (> 17%) and high humidity of materials (more than 30% moisture content)

Double screw extruder has complex structure, request high precision machining, therefore, investment for production facilities is much greater if select this type, so whether select it according to the actual situation.