Description

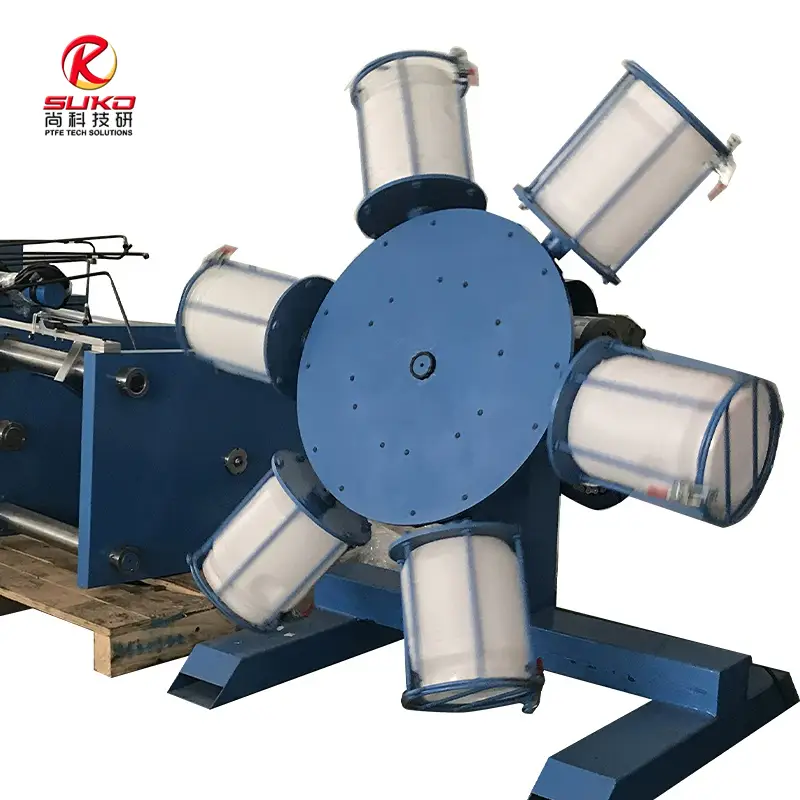

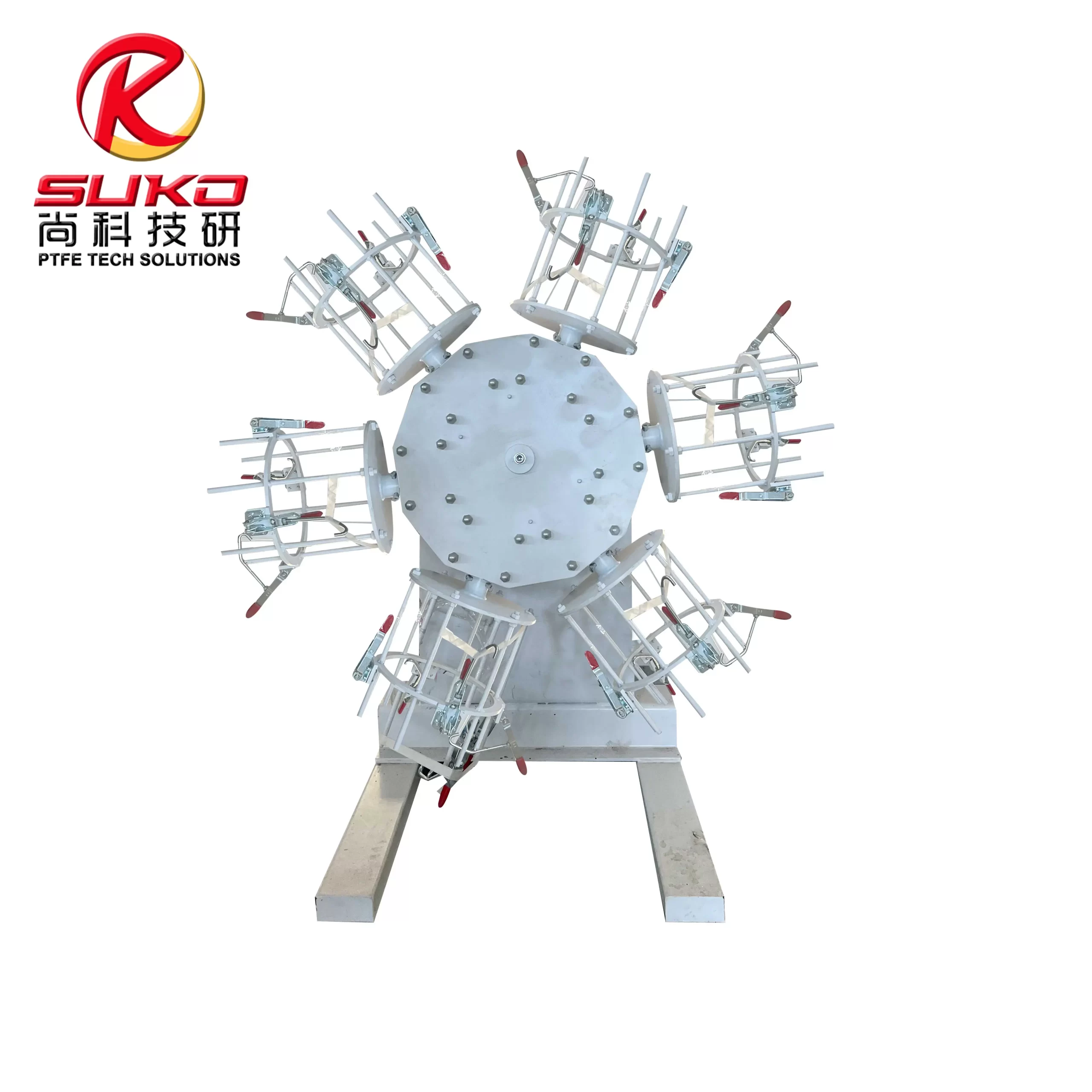

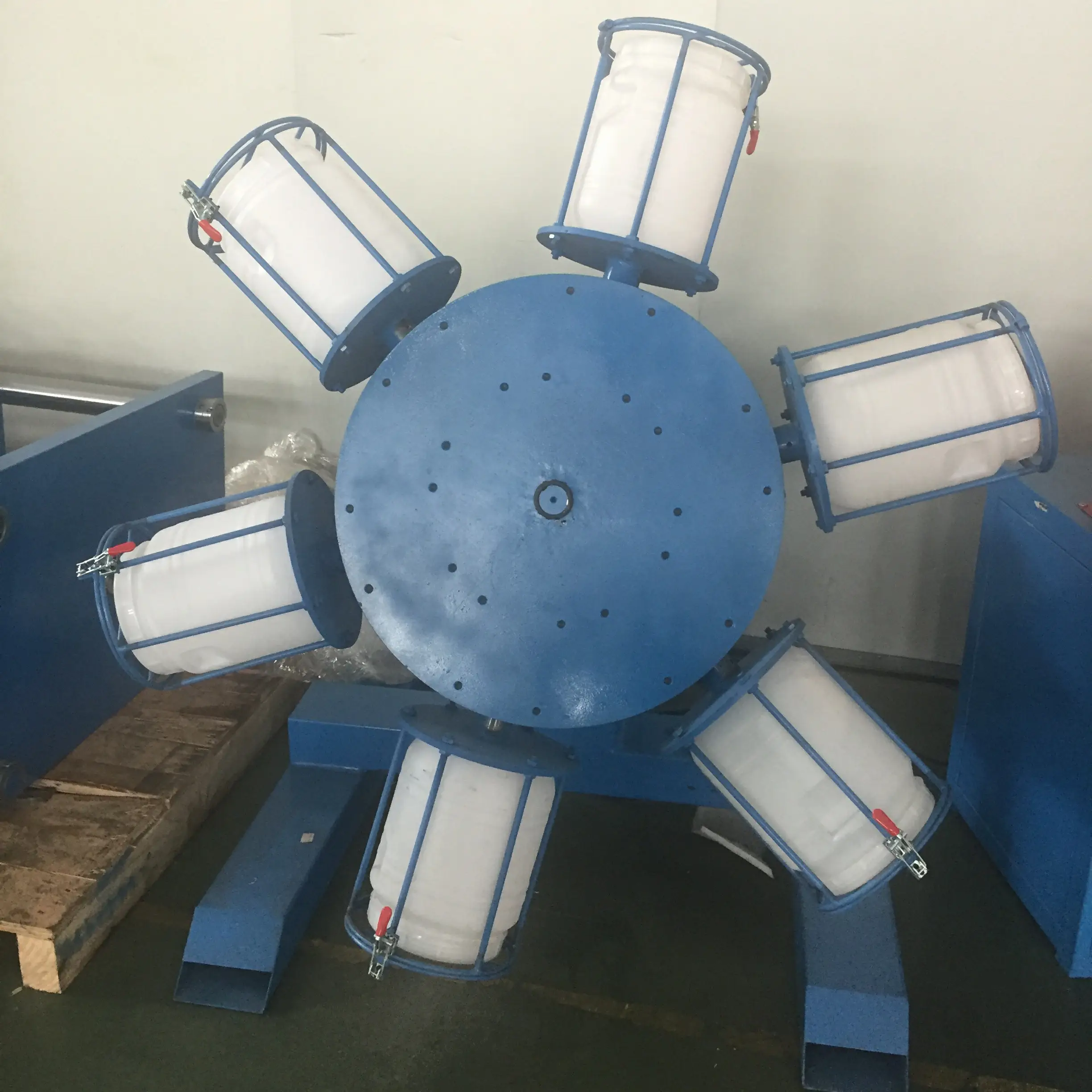

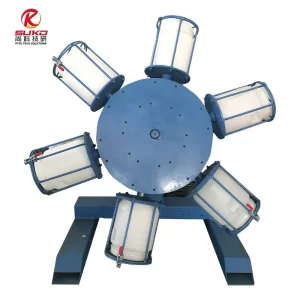

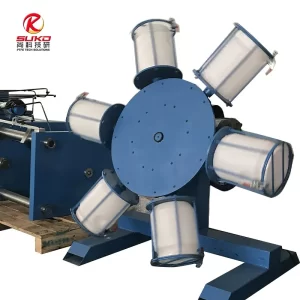

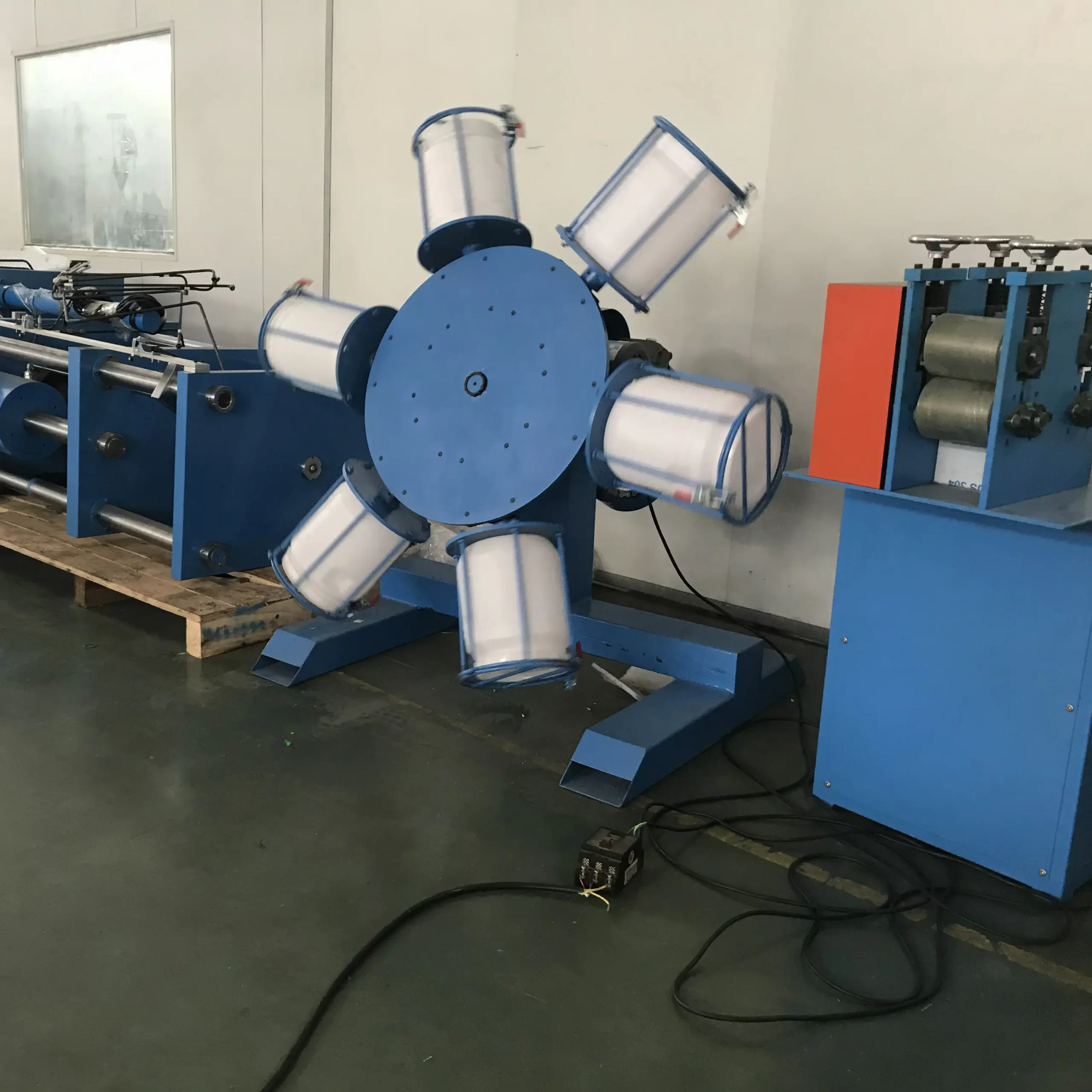

SUKO High-Efficiency PTFE Six-Barrel Mixer

Elevate your PTFE processing capabilities with the SUKO PTFE Six-Barrel Mixer, meticulously engineered for superior blending and homogenization of PTFE powders and compounds. Designed for demanding industrial applications, this robust machine ensures consistent material quality, enhanced productivity, and operational flexibility. Whether you are preparing PTFE resins for molding, extrusion, or other specialized applications, the SUKO Six-Barrel Mixer is your reliable partner for achieving optimal mixing results.

Key Features & Benefits:

Key Features & Benefits:

- Multi-Barrel Efficiency:

- Features six independent mixing barrels, allowing for simultaneous processing of multiple batches, different formulations, or a continuous large-volume operation.

- Significantly increases throughput and reduces overall production time.

- Superior Homogenization:

- Engineered with an optimized mixing mechanism (e.g., specialized agitators, tumbling action – you might need to specify the exact mechanism SUKO uses) to ensure thorough and uniform distribution of PTFE resins, fillers (like glass fiber, carbon, bronze), pigments, and other additives.

- Guarantees consistent material properties, crucial for high-quality end products.

- Robust Construction & Durability:

- Manufactured from high-grade materials, with product contact parts typically made from stainless steel (e.g., SS304 or SS316L) to prevent contamination and resist the corrosive nature of some PTFE compounds.

- Built for longevity and reliable performance in demanding industrial environments.

- User-Friendly Operation & Control:

- Equipped with an intuitive control panel for easy management of mixing parameters such as speed, time, and operational sequence for each barrel.

- May include options for programmable logic controller (PLC) for advanced automation and recipe management.

- Ease of Maintenance & Cleaning:

- Designed for straightforward access to mixing barrels and components, facilitating quick cleaning and material changeovers, minimizing downtime.

- Safety Focused Design:

- Incorporates essential safety features, such as emergency stops, safety interlocks on access points, and overload protection to ensure operator safety and equipment protection.

- Versatile Applications:

- Ideal for mixing various grades of PTFE virgin powders.

- Suitable for blending PTFE with diverse fillers and pigments.

- Perfect for preparing compounds for rod, tube, sheet, and custom molded part manufacturing.

Typical Applications:

- Preparation of PTFE molding powders.

- Blending filled PTFE compounds (e.g., glass-filled, carbon-filled, bronze-filled PTFE).

- Mixing colored PTFE compounds.

- Homogenizing different batches of PTFE for consistent quality.

- Research and development of new PTFE formulations.

- Large-scale industrial production of PTFE semi-finished and finished products.

Why Choose the SUKO PTFE Six-Barrel Mixer?

SUKO is a trusted name in PTFE machinery, committed to delivering innovative and reliable solutions. Our Six-Barrel Mixer embodies our dedication to quality, efficiency, and customer satisfaction, helping you achieve superior processing outcomes and a competitive edge in the market.

Technical Specifications:

| Model | V Type Mixer | Three-dimensional Mixer | Six Barrel Mixer |

| Barrel Volume | 50-2000L | 50-1500L | 30-75L |

| Type of Mixtures | PTFE+Other Powders | PTFE+Other Powders | Special Mixer for Powder Additives |

| Mixing Weight | 15-500kg | 15-650kg | 10-30kg |

| Mixture Coefficient | 0.3-0.4 | 0.7 | 0.7 |

| Mixing Time | 1-60 Minutes (Adjustable) | 1-60 Minutes (Adjustable) | 1-60 Minutes (Adjustable) |

| Running Speed | Freely adjust according to needs | ||

| Material | 304 Stainless Steel | ||

| Voltage/Hz/PH | 380V 50Hz 3P | 380V 50Hz 3P | 380V 50Hz 3P |

Contact Us for More Information:

Discover how the SUKO PTFE Six-Barrel Mixer can optimize your production line. For detailed specifications, a customized quotation, or to discuss your specific processing needs, please get in touch with our expert team.

- Visit our Website: http://ptfe-machinery.com

- Email Us: info@ptfe-machinery.com

- Contact Page: https://ptfe-machinery.com/contact/

We look forward to helping you achieve excellence in PTFE processing!