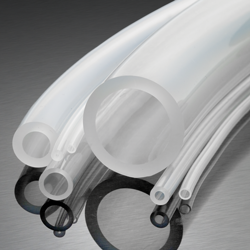

Polytetrafluoroethylene (PTFE) tubing is widely used in the medical field because of its excellent chemical stability, high temperature resistance, corrosion resistance and flame retardancy. PTFE hose can not only be used to transport various drugs and biological products, but also can be used to transport high temperature and high pressure gas and liquid, so it is widely used in the medical field.

First, PTFE hose can be used to transport biological products. Various chemical reagents and solvents are used in the preparation and storage of biological products. PTFE hoses can withstand the corrosion of these chemicals and will not react with biological products, ensuring the purity and quality of biological products. In addition, the surface of PTFE hose is very smooth, which will not cause friction and abrasion, and will not cause any damage or influence on biological products.

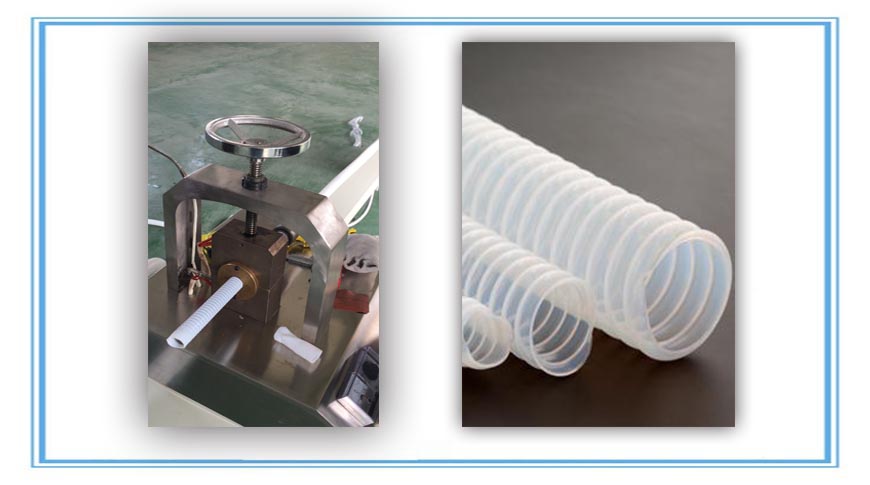

Secondly, PTFE hose can be used to transport high temperature and high pressure gas and liquid. PTFE hoses can withstand high temperature and high pressure environments, and will not be deformed or broken due to changes in temperature and pressure, ensuring the safe delivery of gases and liquids. In addition, the surface of PTFE hose is very smooth, which will not cause resistance and obstruction to the flow of gas and liquid.

Finally, the flame-retardant properties of PTFE hoses also make them widely used in the medical field. The places where medical equipment and instruments are used usually require a high degree of fire prevention. The flame retardant properties of PTFE hoses can effectively reduce the occurrence of fires and ensure the safe use of medical equipment and instruments.

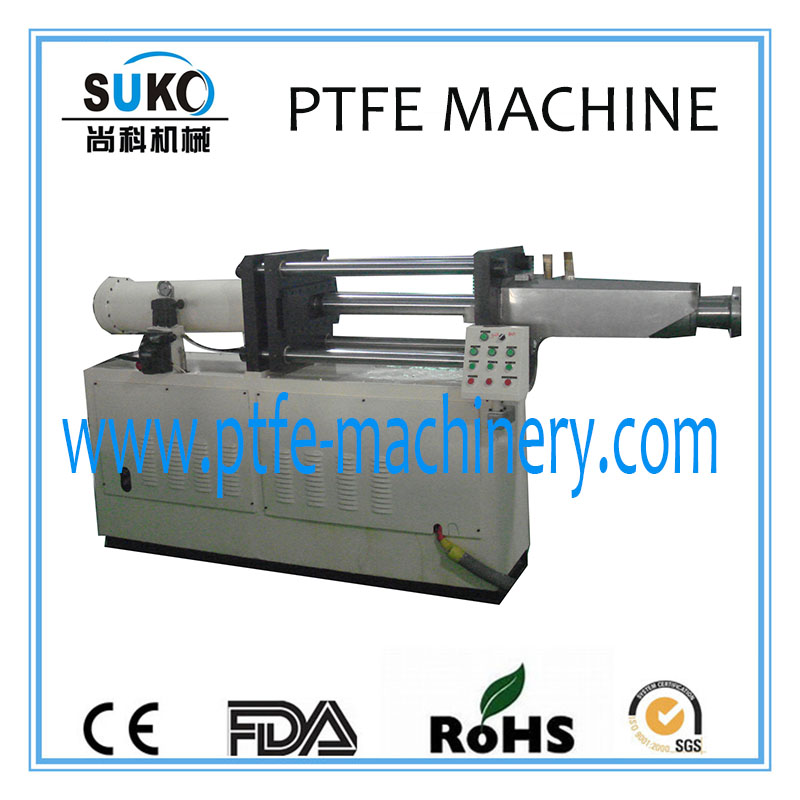

Although PTFE hose has many advantages, its relatively high price may limit its application in some medical fields. In addition, the manufacture and processing of PTFE hoses are more difficult and require certain skills and experience.

In short, PTFE hoses are widely used in the medical field, and their excellent chemical stability, high temperature resistance, corrosion resistance and flame retardancy make them an indispensable and important part of the medical industry.