Moulding Machines

The Ultimate Guide to Switching from Manual to Automatic PTFE Moulding Machines: Benefits and Implementation Tips

The Ultimate Guide to Switching from Manual to Automatic PTFE Moulding Machines: Benefits and Implementation Tips Hey there, if you’re knee-deep in the world of …

5 Common Defects in Teflon Seal Production & How a Precision Machine Solves Them

If you’re knee-deep in making teflon seals or PTFE gaskets, you probably know how tricky it can get. I mean, one little slip-up in the …

Top 5 Benefits of Using High-Precision Automatic PTFE Molding Machines in Manufacturing

If you’re in the manufacturing world, especially dealing with stuff like Teflon components, you’ve probably wondered if upgrading to something like a high-precision automatic PTFE …

5 Key Challenges in Sealing Aggressive Chemicals & How PTFE Gaskets Solve Them

In the high-stakes world of chemical processing, the smallest component can have the biggest impact. A single failed seal can lead to catastrophic consequences, including …

Best cutting solution for sealing PTFE gaskets

PTFE gaskets, also known as Teflon gaskets, are widely used as sealing and filling materials in petroleum, chemical, pharmaceutical, electric power, steel and other industries …

TEFLON GASKETS SEE SIGNIFICANT GROWTH POTENTIAL DUE TO GROWING DEMAND FROM EMERGING MARKETS

Teflon gaskets are acid and alkali resistant, high temperature resistant, and resistant to various organic solvents, and have been widely used in the chemical and …

INTRODUCTION AND CLASSIFICATION OF PTFE GASKETS

PTFE gaskets are flat gaskets, V-shaped gaskets, piston rings, ball valve gaskets, etc., made of Teflon rods, tubes and plates by mechanical turning or cutting. …

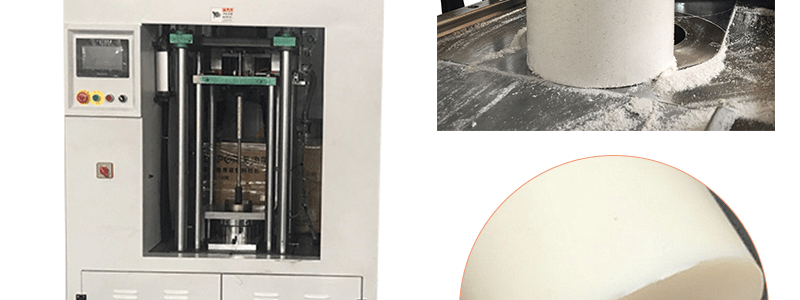

WHAT IS PTFE MOLDING MACHINE ? AND PTFE MOLDING PROCESS

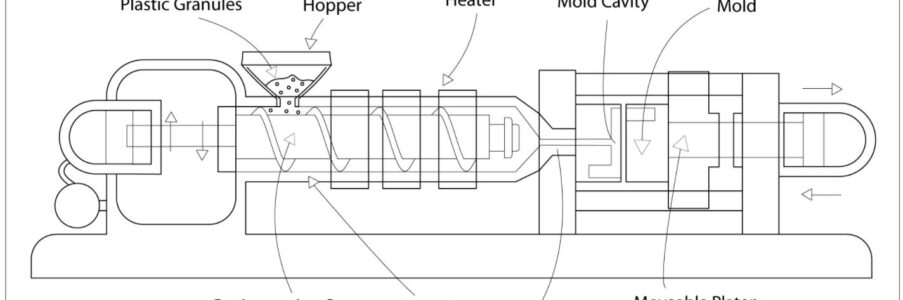

How does injection moulding work?

Injection moulding along with extrusion ranks as one of the prime processes for producing plastic articles. It is a fast process and is used to …