Nylon membranes for filtration using syringe filter devices and which membrane can be used with different solutions and or sovlents.

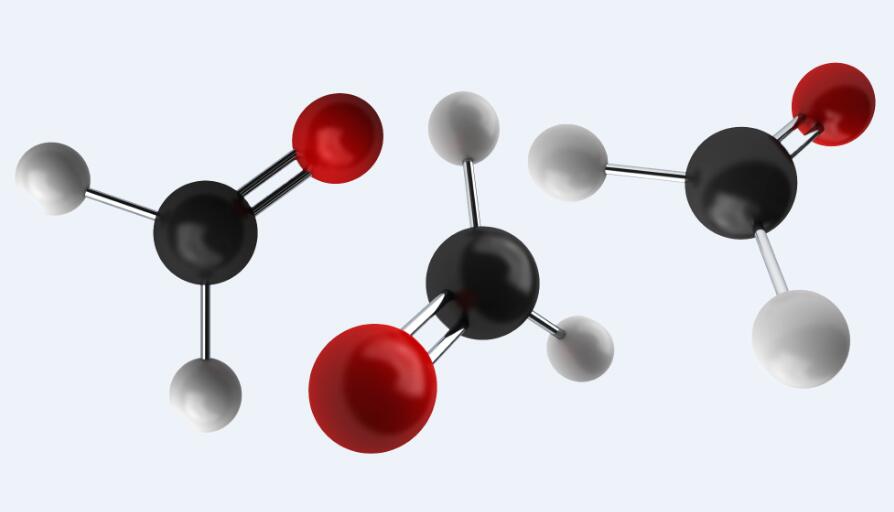

PTFE as a membrane for syringe filters is considered to be more “chemically resistant” and Nylon to be the most “extractable free” for HPLC or dissolution testing. The simple explanation of the differences is that chemical resistance is defined as the durability of the membrane to withstand some harsh solvents (normally not used in HPLC or dissolution testing).

The PTFE membranes still have extractables that usually dissipate or become undetectable after the first 2-3 mls of filtrate are discarded but these membranes can have extractables even after the first 2-3ml (which will vary from supplier to supplier based on the quality of PTFE used). It should be noted that PTFE is hydrophobic by nature so most water based solutions have a hard time penetrating the membrane and require excessive hand pressure to use. This back pressure can be circumvented by “pre-wetting” the membrane with methanol with will allow aqueous based solutions to be filtered.

Some filter manufacturers will use surfactants in the PTFE membrane to make them more water compatible. If eluting surfactants are not of concern, this technology may work well.

Some solvents or solutions are not recommended for use with Nylon membranes as they may “swell” the membrane and or make them weak in that the membrane may disintegrate or simply burst allowing non filtered solution to pass through. However, for other more compatible solutions (most HPLC solvents and solutions) Nylon will provide the most “extractable free” membrane available and is hydrophilic which makes it good for use with water based solutions. Many organic solvents are very compatible with nylon.

Chlorinated solvents, strong acids and strong bases should be avoided when using Nylon membranes.