Fluoropolymers have excellent, almost universal chemical resistance. They can be used both at high and very low temperatures (-260 to +260°C). They also possess outstanding resistance to weathering (UV-stability).

Due to the low coefficient of friction, they are often used as sliding materials or as corresponding additives in other high-performance plastics.

TECAFLON PVDF (PVDF)

Polyvinylidenefluoride (PVDF) – TECAFLON PVDF – is an opaque, semi-crystalline, thermoplastic fluoropolymer. PVDF is characterized by excellent chemical stability, without having the disadvantages of low-mechanical values and/or processing difficulties which can be experienced with other fluoroplastics.

- low density compared to other fluoropolymers

good mechanical strength compared to other fluoropolymers

high permanent operating temperature (140°C)

practically no moisture absorption

good dimensional stability

high chemical resistance

good resistance to hydrolysis

weather-proof

radiation resistant

good electrical insulator

high abrasion resistance

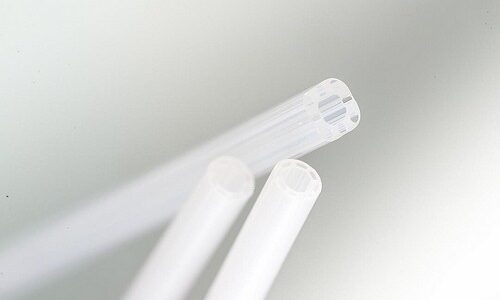

TECAFLON PTFE natural (PTFE)

Polytetrafluoroethylene (PTFE) – TECAFLON PTFE natural – is a semi-crystalline fluoropolymer with an unusually high chemical and thermal resistance (-200 to +260°C, temporarily up to 300°C). In addition, this thermoplastic material has excellent sliding properties, a non-stick surface and the best insulating properties. This is in contrast, however, to low mechanical strength and a high specific gravity, compared to other plastics. In order to improve the mechanical properties, PTFE can be used as a compound reinforced with additives such as glass fibre, carbon or bronze. Due to its structure, this material is formed into semi-finished products using a compression processes and machined afterwards with cutting/machining tools.

- extremely high chemical resistance

very good temperature resistance (-200-+260°C, temporarily up to 300°C)

very low coefficient of friction (static friction = sliding friction)

extremely low surface tension (practically no materials stick to PTFE -> difficult to adhere to or weld)

high coefficient of thermal expansion

relatively low strength/rigidity

low dielectric constant

non-combustible