Plastic PTFE Paste Extruder Machine Features:Adopt adjustable speed to accommodate pitch ,don’t need to change gear;High productived efficiency production three times than present usual machine per hour ,the max production reach to 98m/hour;Low noise ,transmission and pulling system adopt absorbing sound ,reducing shake and inserting equipment;Easy maintenance ,transmission flexible,structure easy install and remove……

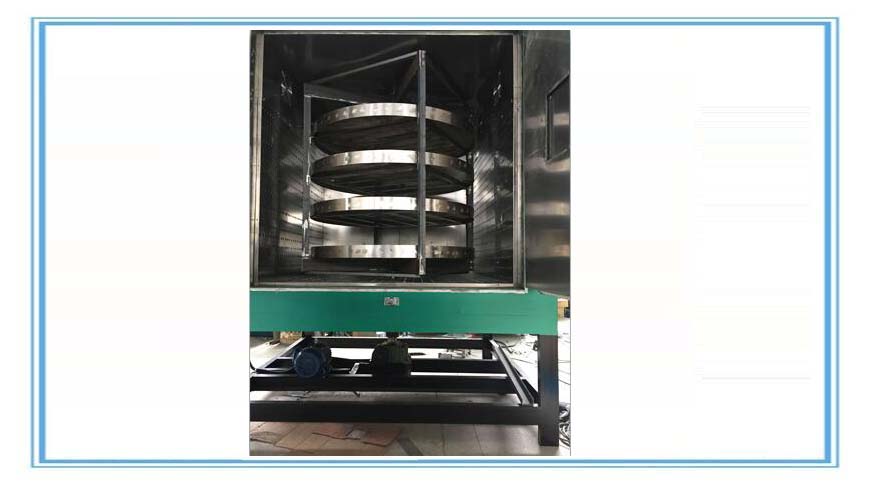

Paster Extrusion tube process:PTFE Fine Powder raw material →Sifting →Mix with solvent→ Heating→ Performing → Extrusion→ Sintering → Finished Tube.

| Paste Extruder | Type & Technical Data | |

| DX-D01 (suit for 25-60 lodaing cavity)

OD:2mm-6mm |

PTFE Paste extrusion Hose Main machine : 30KW power 380V 50Hz one key start with hydraulic drive.1.2M high for material load cavity.

WorkBlank machine : 3KW with 380V 50Hz Hydraulic drive PTFE blank high with 300-600mm. Furnace : 18KW 380V 50Hz with total high 8.5M 500 degree temperature. |

|

| DX-100(suitable for 60-120 loading cavity)

OD:6MM-60MM -2 loading cavity |

FE Paste extrusion Hose Main machine : 30KW power 380V 40Hz one key start with hydraulic drive.1.5M high for material load cavity.

WorkBlank machine : 3KW with 300V 50Hz Hydraulic drive PTFE blank high with 300-600mm. |

PTFE Hose Machine Specifications

* Long service life through solid workmanship and use of high quality components

* Low wall thickness tolerance through self-centering mandrel and special nozzle

* Measurement transducer like pressure, force and ram speed for permanent control of the extrusion process and extrusion speed

* Hydraulic closure with high closing force for quick loading of the extruder

* Special pre-form press with pre-form preparation device for multiple loading of the loading carriage i.e. extruder

* Electrically adjustable mandrel

* Measuring and controlling system for constant extruder speed

* Controlling system for constant speed of the extrudate

* User-friendly and maintenance-free system

* The paste extrusion systems are designed especially to costumers requests

* Automatic adjustment of the total system as well as recording of the formula

* Operating through touch screen and recording of the extrusion process parameters