PTFE, also known under the brand name Teflon, has the lowest coefficient of friction of any known solid material and melts between 260°C and 327°C.

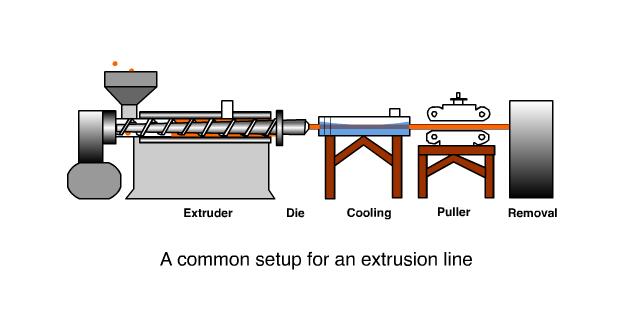

It’s fairly hard and fairly stiff too, so it’s ideal for parts including things low friction bushings to main assembly parts. Thermoplastics often swell just before they melt, so PTFE tube inserts are used in many extruder hot ends so that the swelled plastic slides on this insert, instead of wedging itself in, preventing extrusion. PEEK tubing can also be used for this purpose.

PTFE is used in lubricants, and PTFE-filled oil is highly recommended by many in the community as being the best all-round low friction and inert lubricant for machines. PTFE is also sold in very thin tape, known as plumbers tape or thread-sealing tape.

Despite it’s relatively low melting temperature, “liquid” PTFE is much more of a thick gel than a true liquid. Because of this it cannot be injection molded; it is shaped and compressed in powder form, and then sintered. For this reason, PTFE is surprisingly expensive. It will likely remain a vitamin, unless powder printing takes off.

Properties

| Property | PTFE (unfilled) | PTFE (25% glass filled) | PTFE (25% carbon filled) |

|---|---|---|---|

| PHYSICAL | |||

| Density (lb/in³) (g/cm³) | 0.078 (2.16) | 0.081 (2.25) | 0.075 (2.08) |

| Water Absorption, 24 hrs (%) | < 0.01 | 0.02 | 0.05 |

| MECHANICAL | |||

| Tensile Strength (psi) | 3,900 | 2,100 | 1,900 |

| Tensile Modulus (psi) | 80,000 | – | – |

| Tensile Elongation at Break (%) | 300 | 270 | 75 |

| Flexural Strength (psi) | No break | 1,950 | 2,300 |

| Flexural Modulus (psi) | 72,000 | 190,000 | 160,000 |

| Compressive Strength (psi) | 3,500 | 1,000 | 1,700 |

| Compressive Modulus (psi) | 70,000 | 110,000 | 87,000 |

| Hardness, Shore D | D50 | D60 | D62 |

| IZOD Notched Impact (ft-lb/in) | 3.5 | – | – |

| THERMAL | |||

| Coefficient of Linear Thermal Expansion(x 10-5 in./in./°F) | 7.5 | 6.4 | 6.0 |

| Heat Deflection Temp (°F / °C) at 264 psi | 132 / 55 | 150 / 65 | 150 / 65 |

| Melting Temp (°F / °C) | 635 / 335 | 635 / 335 | 635 / 335 |

| Max Operating Temp (°F / °C) | 500 / 260 | 500 / 260 | 500 / 260 |

| Thermal Conductivity (BTU-in/ft²-hr-°F) (x 10-4 cal/cm-sec-°C) | 1.70 (5.86) | 3.1 (10.6) | 4.5 (15.5) |

| Flammability Rating | V-O | V-O | V-O |

| ELECTRICAL | |||

| Dielectric Strength (V/mil) short time, 1/8″ thick | 285 | – | – |

| Dielectric Constant at 1 MHz | 2.1 | 2.4 | – |

| Dissipation Factor at 1 MHz | < 0.0002 | 0.05 | – |

| Volume Resistivity (ohm-cm)at 50% RH | >10^18 | > 10^15 | 10^4 |