PTFE is a low-friction material with properties such as corrosion resistance, high temperature resistance, insulation, and non-stick properties, so it is widely used in many industrial fields.

PTFE is complex to process because it is highly inert and inplastic.

This article will introduce the processing methods and precautions of PTFE.

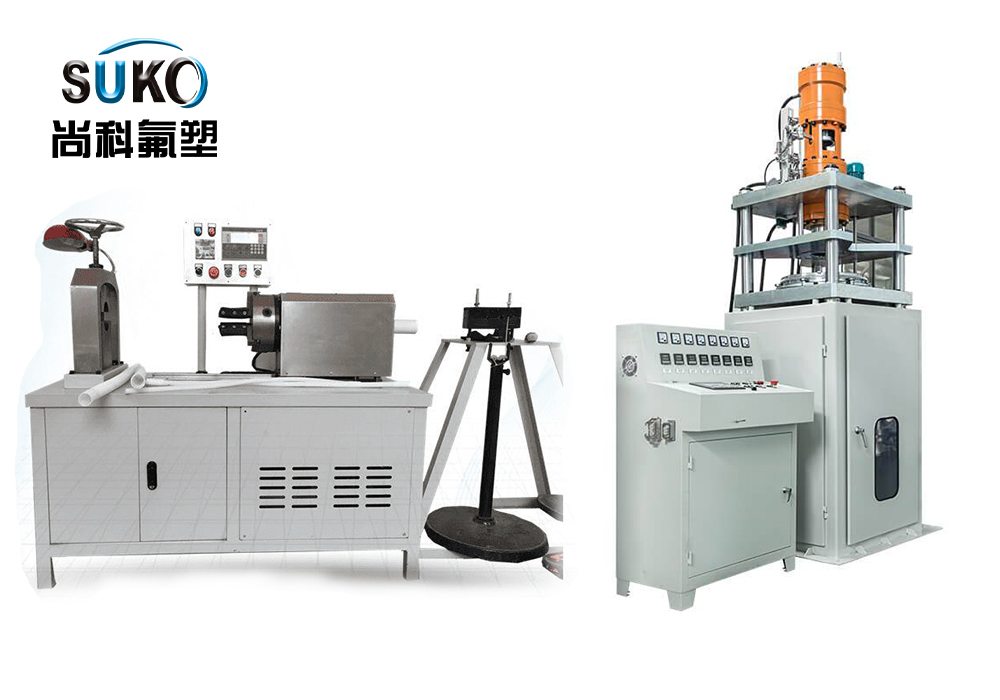

First of all, the processing methods of PTFE include extrusion, compression molding, injection molding and other methods.

Among them, extrusion is the most commonly used processing method.

In the process, PTFE particles are heated and extruded by the extruder into a certain shape of rod, tube or plate.

Compression molding is the process of placing PTFE pellets into a mold and processing them into a specific shape under high temperature and pressure.

Injection molding is done by injecting molten PTFE into a mold and cooling it into a solid shape under high temperature and pressure.

Secondly, the processing precautions for PTFE include the following points:

Temperature control: The processing of PTFE needs to be carried out in a high temperature environment, but too high a temperature will cause the material to sinter or decompose, which will affect the processing quality.

Therefore, the temperature needs to be strictly controlled during the processing, and different processing temperatures and times need to be determined for different processing methods and material shapes.

Pressure control: The processing of PTFE needs to be carried out under high pressure environment, but too high pressure will cause the material to deform or crack.

Therefore, the pressure needs to be strictly controlled during the processing, and different processing pressures and times need to be determined for different processing methods and material shapes.

Selection of lubricants: PTFE has strong non-stick properties, so lubricants are required during processing to reduce friction and improve processing efficiency.

However, improper lubricants will affect the performance of PTFE, so it is necessary to choose a suitable lubricant.

Selection of processing technology: The processing of PTFE needs to choose different processing technologies according to different shapes and sizes.

For complex shapes, multi-pass processing is required to ensure processing quality and efficiency.

In short, the processing of PTFE is a complicated process, which requires strict control of processing temperature, pressure and processing technology.

During the processing, it is necessary to select the appropriate lubricant and process to ensure the processing quality and efficiency.