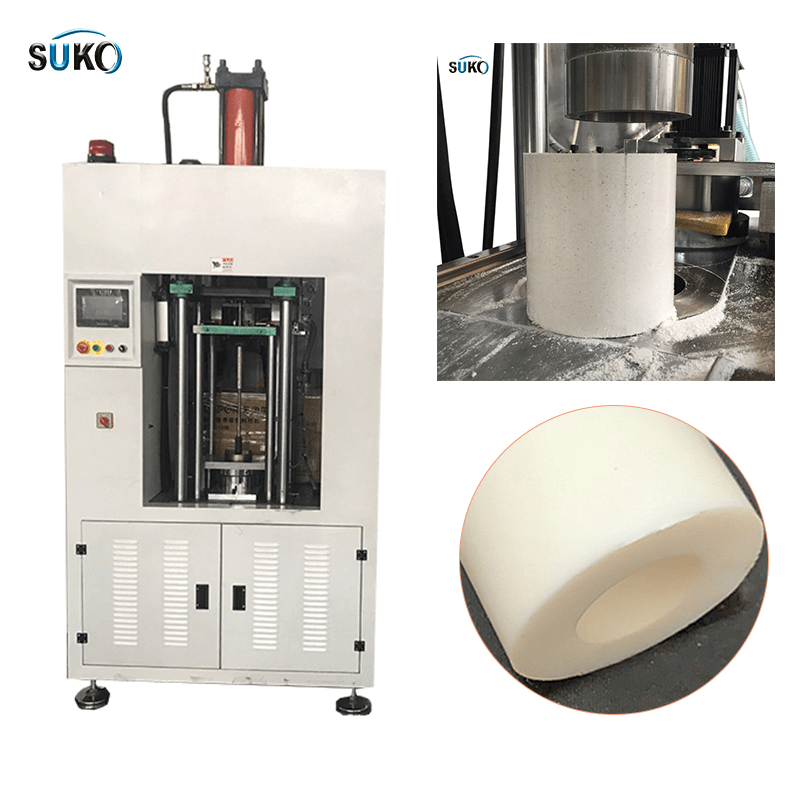

PTFE Paste Extruder is a kind of PTFE pipe vertical extruder which integrates feeding, extruding, heating and forming with high production efficiency. It includes an outer die with a central hole fixed on the frame, a core die; the core die passes through the central hole of the outer die, and a die cavity is formed between the core die and the central hole of the outer die; the die cavity includes an upper extrusion section and a lower forming section; an induction heater is set on the periphery of the outer die in the forming section to heat the outer die; a press die is set sliding on the periphery of the core die above the die cavity, and the press die is connected to a main drive device that drives the press die up and down along the core die to slide in and out of the extrusion section. The die is connected to the main drive device which drives the die to slide up and down along the core die and in and out of the extrusion section; a blocking ring is set on the periphery of the upper end of the outer die, and a material bin is formed between the upper end of the outer die and the inner periphery of the blocking ring for holding the material; a scraper is set at the bottom of the bin; the scraper is driven by the scraper drive device to rotate around the axis of the core die and send the material in the bin into the die cavity.

Equipment line from the beginning of the raw material to the sieve powder, mixing, aging, billet, extrusion, winding, cooling, cut off this complete process,produce a variety of hose products to meet the requirements.

SUKO specializes in the production of tetrafluoro equipment, the main products are tetrafluoro tube bar extruder, molding machine, corrugated tube machine, mixing machine, oven, etc. We export mainly to the domestic market, exporting to more than 40 countries, providing the whole line of solutions and technical guidance; PTFE Paste Extruder is a special equipment developed by the hydraulic extruder design team of Jiangsu SUKO Machinery Technology Co. This machine combines technology, design, reliability and all in one. It brings customers a simple, easy to operate, high performance, low maintenance cost experience, with more savings – time and cost, high output, low energy consumption, long life, easy to operate – touch screen display, and a series of advantages, has a very high productivity in the market. The machine maintains a stable extrusion speed when extruding PTFE to produce accurate, high quality PTFE products. PTFE Paste Extruder is also called: PTFE hollow tube extruder, Teflon capillary tube extruder, PTFE line extruder, PTFE microporous tube extruder, PTFE hollow tube extruder, which can produce outer diameter 0.5mm-70mm PTFE tube material. Adopt plc computer control line. The basic mechanism of extrusion is simple – laminated automatic production of PTFE, equipped with PTFE extrusion unit and peripheral auxiliary machines and accessories, to provide customers with complete PTFE products processing and molding.

The teflon hose it produced can be widely used in military industry, chemical industry, medical treatment, aerospace, mechanical equipment, heat exchange and other fields.

Features of PTFE Paste extruder:

1. Paste extrusion of various specifications of dispersed material tetrafluoride tube

2. Vertical installation extrude, can extrude 2-15 meters per minute

3. Extrusion length can be customized according to requirements

4. Intelligent control of equipment, stable operation;

5. Maintenance is convenient, transmission is flexible, structure is easy to install

6. SUKO provide complete set of equipment, necessary auxiliary equipment and technical solution

7. SUKO provide operation process technical guidance

8. Multi-layer material tube can be extrudedTHEODUCTION OF PTFE PASTE EXTRUDER